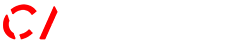

Cab-Sab - Strahlkabinen für Granulat / Korund / Strahperlen

-

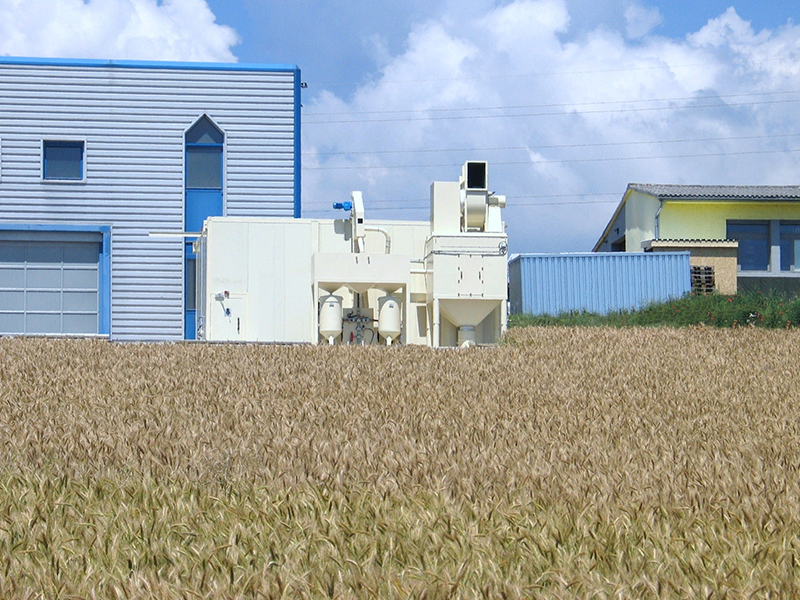

Visit our installations

Sandstrahlraum

Eine „Sandstrahlkabine“ ist eine Anlage, bei der ein Bediener einen Freistrahl mit Druckluft eines Mediums, abrasiv oder nicht, auf ein Produkt richten kann, um ein Sandstrahlen durchzuführen Abisolieren, Polieren, Reinigen oder Hämmern... Es gibt 3 Hauptarten des Sandstrahlens:

StrahlkabineVerwendete Medien: Winkel-/Rundschrot oder Edelstahlschrot. Zum Beizen oder Hämmern zur Behandlung von Stahlteilen.

KorundkabineVerwendete Medien: brauner oder weißer Korund Beizen oder Reinigen hauptsächlich für die Behandlung von dünnen Stahl-, Aluminium-, Edelstahl- oder anderen Legierungsteilen.

PerlenstrahlkabineVerwendete Medien: Glaskugel, Kunststoffmedien, Keramikkugel, pflanzliche Schleifmittel…. Polieren, Reinigen, Hämmern durch Spritzen von Mitteln, die hauptsächlich für die Behandlung von speziellen Geräten aus Edelstahl, Holz, Kunststoff bestimmt sind.

Wir produzieren Kabinen in allen Größen.Diese Kabinen sind standardisiert, vormontiert und werksgeprüft. Für eine Reihe von Abmessungen: Länge: von 4 bis 30 m. Breite: 3 bis 6 m. Höhe: 2,8 bis 6 m. Für Breiten von 3 und 4 m haben wir ein patentiertes Produkt ''CAB-SAB'' entwickelt, das komplett im Werk vormontiert ist und keine Montage, sondern nur eine Installation durch den Kunden auf der Website erfordert.

Diese Art von Produkt ist ideal für Unternehmen der Art:Oberflächenbehandlungsindustrie, Farbapplikatoren, Karosserie, Schlosser, Kesselbauer, Gießer, Hersteller von Industrieprodukten... Unsere Produkte sind normgerecht und können optional ATEX-Normen erfüllen.

Sandstrahlkammer

Die Strahlkabine ist ein wesentlicher Bestandteil der Kabine. Es gewährleistet die Robustheit der Installation und ihre Schalldämmung. Unsere Lautsprecher bestehen vollständig aus einer robusten Rohrstruktur mit doppelwandigen Paneelen aus 100 mm dickem lackiertem Stahl, was ihnen eine normgerechte Schalldämmung verleiht. Seine starre Konstruktion gewährleistet die ordnungsgemäße Funktion der Öffnungen und ermöglicht es ihm, Stößen und besonderem Verschleiß standzuhalten. Unsere Kabinen sind mit verstärkten Flügeltüren mit sandstrahlspezifischen Scharnieren und Verschlüssen ausgestattet. Je nach Nutzung können sie auch mit Sektionaltoren geliefert werden. Die Haupttür hat ein externes Schließsystem und die Nottür (mehrere gemäß den Vorschriften) ist mit einer Schließglocke ausgestattet. Jede Haupt- oder Nottür hat: - ein Schließsensor - eine rote Ampel - ein gepanzertes Sichtfenster mit Innenschutz - ein Doppelgriff Die Bauweise der Kabine ermöglicht einen nachträglichen Abbau oder Ausbau.